What Is Polypropylene Used For?

Polypropylene (PP) is a versatile thermoplastic polymer that has revolutionized various industries with its exceptional properties and cost-effectiveness. From packaging and automotive to textiles and medical, polypropylene finds extensive use in numerous applications. In this blog post, we will explore the diverse applications of polypropylene and its significant contributions to different sectors.

Packaging Solutions

Polypropylene is widely employed in the packaging industry due to its outstanding characteristics. It is used for manufacturing containers, bottles, caps, and closures, providing durability, moisture resistance, and excellent barrier properties. PP's lightweight nature and ability to withstand varying temperatures make it ideal for food packaging, pharmaceuticals, personal care products, and more.

Automotive Components

Polypropylene is extensively utilized in the automotive industry for the production of various components. Its high impact strength, chemical resistance, and ability to withstand heat make it suitable for manufacturing bumpers, interior trims, dashboards, door panels, and battery cases. PP's lightweight nature also contributes to improving fuel efficiency in vehicles.

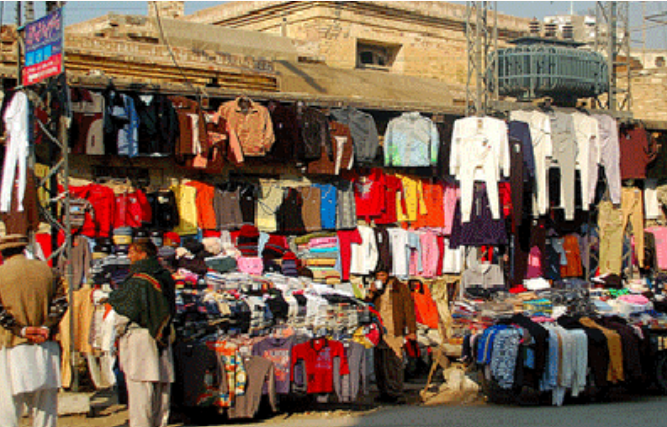

Textiles and Fibers

Polypropylene fibers are widely used in the textile industry, offering unique properties that make them desirable for different applications. PP fabrics are lightweight, moisture-wicking, and resistant to fading, making them ideal for sportswear, activewear, and outdoor apparel. Polypropylene fibers are also utilized in geotextiles, upholstery, and carpeting.

Medical Devices and Equipment

Polypropylene's excellent biocompatibility makes it a preferred material for medical devices and equipment. It is used in the production of syringes, surgical trays, catheters, implantable devices, and more. PP's compatibility with various sterilization methods ensures the safety and reliability of medical products.

Electrical and Electronic Applications

Polypropylene's electrical insulation properties make it suitable for electrical and electronic applications. It is used in the production of cable insulation, capacitors, connectors, and other electrical components. PP's low electrical conductivity and high dielectric strength contribute to the safety and efficient performance of these devices.

Household Goods and Consumer Products

Polypropylene plays a significant role in the manufacturing of various household goods and consumer products. It is used for producing items such as food containers, storage bins, furniture, toys, kitchenware, and appliances. PP's durability, ease of processing, and resistance to chemicals make it an excellent choice for everyday consumer products.

Agriculture and Horticulture

Polypropylene finds applications in the agricultural sector, where it is used for manufacturing agricultural films, greenhouse coverings, and crop protection materials. PP's ability to resist UV radiation, moisture, and chemical exposure ensures the durability and effectiveness of these agricultural solutions.

Building and Construction

Polypropylene is utilized in the construction industry for different purposes. It is used in the production of pipes, fittings, insulation materials, roofing membranes, geotextiles, and waterproofing products. PP's high chemical resistance, durability, and ability to withstand extreme weather conditions make it a reliable choice for building and construction applications.

Polypropylene's versatility has positioned it as a key material in a wide range of industries. Its exceptional properties, including durability, chemical resistance, moisture resistance, electrical insulation, and lightweight nature, have made it indispensable in packaging, automotive, textiles, medical, electrical, household, agriculture, and construction sectors. As technology and innovation continue to advance, polypropylene will undoubtedly find even more applications, driving progress and efficiency across various industries.

.png)