Business Intelligence (BI) and Enterprise Resource Planning (ERP) systems have become increasingly important for manufacturing businesses globally in recent years. These systems provide a wealth of information and capabilities that can help manufacturing companies streamline their operations, improve efficiency, and make better-informed decisions.

Business Intelligence refers to the tools, technologies, and processes that enable organizations to collect, process, and analyze large amounts of data. By using BI, manufacturing companies can gain a deeper understanding of their operations and identify areas for improvement. For example, BI can help identify trends in production, highlight bottlenecks in the supply chain, and provide insights into sales and marketing effectiveness. This information can then be used to make data-driven decisions that help the company stay competitive and meet its goals.

ERP systems, on the other hand, are designed to help organizations manage all of their core business processes in one integrated system. This includes everything from accounting and finance to production and inventory management. By having all of this information in one place, manufacturers can gain a complete picture of their operations, making it easier to identify areas for improvement and make data-driven decisions.

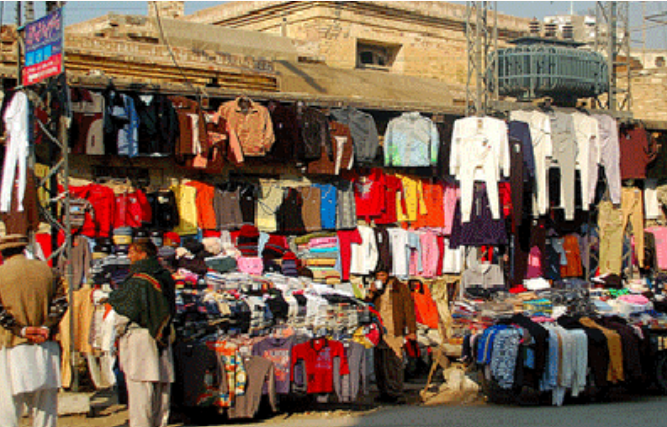

In the textile manufacturing industry, ERP systems can be particularly valuable as they can help companies optimize production processes, reduce costs, and improve the accuracy of their inventory management. For example, an ERP system can help a manufacturer identify the most efficient production methods, track inventory levels in real time, and manage production schedules to ensure the timely delivery of products to customers.

Another advantage of using an ERP system in a manufacturing business is the ability to track and manage the entire supply chain. This includes suppliers, distributors, and customers, which can help companies ensure that they are meeting their obligations and taking advantage of any opportunities to improve their operations. With the help of an ERP system, manufacturing companies can also reduce the risk of production disruptions and minimize the impact of any unexpected changes in demand or supply.

Manufacturers often look for ERP with business intelligence integration because it provides a comprehensive solution that helps them make informed decisions and improve their operations. By having both ERP and BI integrated, manufacturers can benefit from the following advantages:

Real-time data access

With an integrated ERP and BI solution, manufacturers can access real-time data from multiple sources, including production, inventory, and financials. This helps them make informed decisions and respond quickly to changes in the market or supply chain.

Improved data accuracy

Integrating ERP and BI eliminates the need for manual data entry and reduces the risk of data errors. This leads to improved data accuracy, which is critical for making informed decisions.

Better decision-making

With a comprehensive view of their operations, manufacturers can identify trends and make data-driven decisions that help them improve efficiency, reduce costs, and increase profitability.

Increased efficiency

An integrated ERP and BI solution streamlines operations by automating manual processes and providing real-time visibility into key performance metrics. This helps manufacturers reduce costs and increase efficiency.

Customizable dashboards

Manufacturers can create customized dashboards that provide a real-time view of key performance metrics, including production, inventory, and sales. This helps them quickly identify areas for improvement and make informed decisions.

Scalability

As manufacturers grow and their operations become more complex, an integrated ERP and BI solution provides the scalability needed to accommodate changing requirements.

Business Intelligence and ERP systems can be powerful tools for manufacturing companies, providing valuable insights into operations and helping companies make informed decisions. By leveraging these systems, manufacturing businesses can improve efficiency, reduce costs, and stay ahead of the competition. If you are a manufacturer, consider investing in these technologies to take your operations to the next level.

.png)

_1000.png)